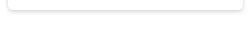

Wastewater Treating Flowchart

Auto Bar Screen Series

- Hospital, school/government agencies, livelihood sewage, municipal wastewater treatment plant, Industrial area comprehensive wastewater treatment plant, pump station and all kinds of Industrial wastewater … etc. for removing the forepart dross, suspended solids and heavier sediments of the above wastewater treatment and protect the post-treatment equipment (pump) to avoid clogging from the impurity. The raking teeth opening will be from 4mm to 100mm for removing the fine /medium/large/especially large impurity from the above wastewater.

Solid-Liquid Separating Machine Series

- Removing and separating of the suspended solid, floating impurity, settling matter of the forepart treatment, to smooth processing flow, reducing the subsequent load and equipment protection.

- For the floating matter, solid mater removing and solid-liquid separating of various industrial waster water pre-treating stage.

- For the engineering drainage and large-size waste water treatment of municipal sewage , paper & pulp sewage, leather & tannery sewage , food industry sewage , butchery industry sewage , fiber industry sewage , chemical industry sewage…etc.

- For decreasing the post treating fees and protecting the post-treatment equipment (sludge pump) to avoid clogging by the impurity.

- For the filtering, separating and removing of the dregs and particle residue of various industries and food industrial processing.

- Adopted the wedge wire screen and selected the sieve slots from 0.3 to 5.0mm for the proper application.

The Oil-Water Separating Machine for Oil Floating Waste Water (Oil/Water Separating Equipments)

- For recycling the separating of floating oil and waste water produced from all kinds of industries.(not including emulsifying condition and dregs floating oil…etc)

- The above equipment especially suitable for the applications of steel / iron industry, metal industry, metal processing industry and metal surface treatment Industry…etc.

- Oil absorption medium – fiber filter belt and stainless steel belt for selection depending on the type of oil film.

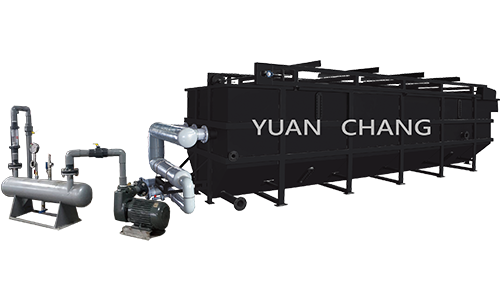

Package Type High Efficiency Dissolved Air Flotation System

- For the solid and liquid separation of various industry sewage/chemical coagulation treatment.

- For the oil and water separation of oil/grease waste water treatment.

- For the treatment of the slurry thickening and reduce the treating cost.

- Our DAF be designed for the sludge having smaller specific gravity and smaller operating space and with shorter staying time and stronger air flotation removing ability For the paper pulp recycling of paper mill.

Polymer Dosing Pump & Powder Automatic Dispensing Dissolvers

- Specially suitable for municipal waste water treating plant, Industrial waste water treating plant and industry required the flocculant solution feeding.

- Extensively applied to sewage dewatering、waste water treatment and various processing industry (food, chemical, dyeing, papermaking …etc.).

- Suitable for the powder’s dissolving-feeding of the various dry powder, pellet, flocculant and condensing liquid.

Slurry Thickeners

- With slurry concentrated reduction function, special for the various lower concentration slurry (S.S. 0.4 ~ 1.0%) and increasing the concentration to 3.5~12% to reduce the slurry treating cost.

- Special for the larger slurry volume’s treating of the various Industrial area comprehensive wastewater treatment plant, municipal wastewater treatment plant, excretion plant, water purification plant…etc. For the solid and liquid separation of various industrial processing treatment of paper & pulp, fiber, chemical, food, plastic, metallurgy, mining…etc. For the solid and liquid separation of the fruit processing industry, vegetable processing industry and the filtering-removing of the dross pellet of the winery industry and pickled industry. Pre-filtering of tap water intaking, recycling rainwater filtration.

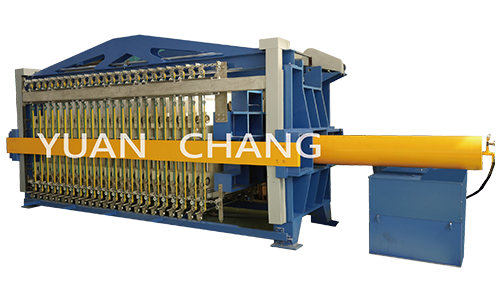

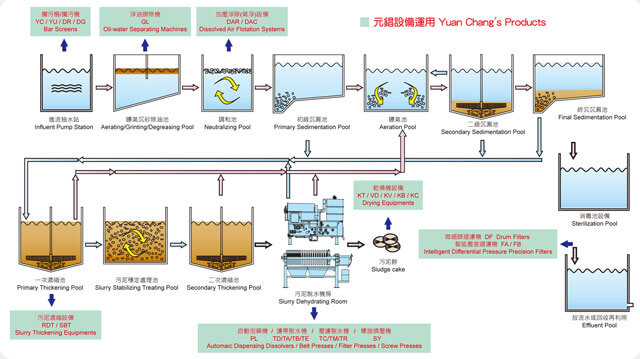

Belt Presses (Conditioning + Thickening + Dehydrating→Three-in-one)

- Obtained the multiple product patents of Germany / U.S.A. / China / Taiwan. The newest super water saving high pressure (20 kg/cm²) reciprocating type washing system(total water consumption is only one-third ~ half of conventional fixed type washing system.). Conditioning / thickening / dehydrating belt presses with optimum design , easy operation and excellent treating result. The slurry dewatering of the various industrial waste water, butchery, livestock factories, city sewer, excretion, water purifying …etc. Solid and liquid separation processing for food&beverage, chemical industry, mining industry …etc. The filtrate reusing system for filter belt washing(optional accessory), can effectively save the subsequent return water treatment costs.

Filter Presses

- This small experimental filter press be designed for a small amount of sludge or food, chemical, manufacturing (medicine) drugs, dye (pigment) materials, the recycling industry and other processes used in the experimental tests.

- The water content’s rate of cake:25∼75% after treatment and high economic results.

- The various industrial waste water, inorganic, mixing sedimentary waste slurry dehydrating treatment.

- Stone material / construction mud / river, water purification plant, reservoir mud’s dehydrating treatment.

- Food, pharmacy, chemical industry, dye(pigment), ceramics, mining and other related industrial process, solid and liquid separation dehydrating treatment.

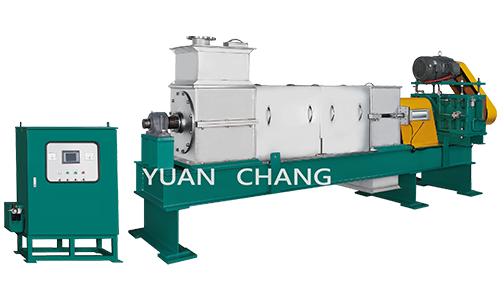

Extruding / Screw Presses

- Solid-liquid separating dehydration for pig, cow, chicken, duck manures and other livestock manures.

- Pulp paper slurry, dying fiber slurry, leather & tannery slurry, city mixed raw slurry, civil engineering muck, livestock dung… etc dehydration.

- It can be dewatered by the 2nd squeezing for the sludge cake after belt press dehydrating to decrease the water content rate of sludge cake from 85% to 48%(depends on the feature of the slurry), reduce the cost of the post disposal effectively.

- Further extruding and dehydrating for various waste recycling industry.

- Food industry wine dregs, coffee grounds, food residue, kitchen waste, sea food processing…etc. extruding dehydration.

- The dehydration for dregs with fiber-like or particle-like relative material…etc.

- For those who need to get less water content reduction.

- Pulp paper slurry, dying fiber slurry, leather & tannery slurry, city mixed raw slurry, civil engineering muck, livestock dung… etc dehydration..

- It can be dewatered by the 2nd squeezing for the sludge cake after belt press dehydrating to decrease the water content rate of sludge cake from 85% to 40%(depends on the feature of the slurry), reduce the cost of the post disposal effectively.

- Further extruding and dehydrating for various waste recycling industry.

- Food industry wine dregs, coffee grounds, food residue, kitchen waste, sea food processing…etc. extruding dehydration.

- The dehydration for dregs with fiber-like or particle-like relative material…etc.

- For those who need to get high water content reduction.

Drying Equipments

- Suitable for the drying of the industrial sludge(chemical) after dewatering.

- Reduce sludge volume: 50%, sludge weight: over 70% and reduce disposal cost after drying.

- The power consumption of drying one kilogram’s sludge cake could be 0.3~0.55 KWH, you may make use of daily off-peak tariff to operate the above equipment to get high economic benefit.

- Closed type, circulating, low noise and no dust, no secondary pollution problems.

- Specially designed for electroplating surfacing treating, metal processing, automobile Industry, steel industry.

- After drying, the water content rate of sludge cake can be reduced to 10~30% and get best result.

- Adopted low temperature heater with closing and screw agitating type(simple scrubber washing device included), low noise, no secondary pollution.

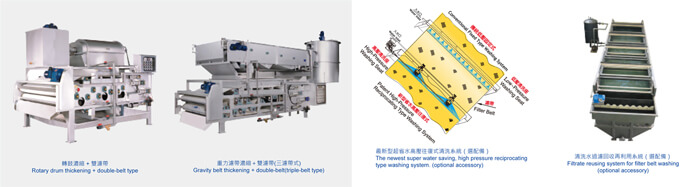

Filtering Equipments

- Pure water, reverse osmosis, ion exchange pretreatment.

- The central air conditioning system, iron and steel, petrochemical, paper making, metallurgy, heat treatment and other industries cooling water filter.

- The reclaimed water, swimming pool cycle water, car wash cycle water and ships' ballast water filtration.

- Groundwater, surface water, rust removing filtering.

- The municipal green spray, agricultural spray filtering.

- Adopted the above goods after the sedimentary tank or dissolved air flotation system of the 2nd class treatment and a good substitute for the fine filtering of the sand filter (tank) to reach the high discharging standard.

- To treat the removing of the suspended solids and impurities of the discharge water after the various industrial waste water treatment for the recycling usage.

- The particle removing of the fine suspended solid of the 3rd class waste water treatment.

- The filtration treatment of the processing water of the various industry for the recycling using (non suspension matter on liquid level).

- For the filtering and separating treatment of impurities for the river water / tap-water / rainwater / groundwater.

- For high density aquaculture water purification loop filter use.

Complete Sets of Processing Equipment of Kitchen Waste into Organic Fertilizer (Customized Products)

- It can feed the family kitchen, restaurant kitchen waste and rapidly make into organic fertilizer.

- It can feed the cattle, pigs, chickens’ manure and rapidly make into organic fertilizer.

- It can feed the market waste(leaves, stems, perishable material) and rapidly make into organic fertilizer.

- The use of screening(manual type), crushed, adding enzymes & sub-material, screw extrusion dehydration, enzymes pyrolysis, drying & sterilization…processing procedures to achieve fast ripening and get a high economic efficiency.

- Continuous process, short enzymes ripening time, efficiency can reach more than 95%.

- Made garbage into gold, creating high economic value from the reuse of resources.

- Treating capacity(8hr/day) : 5, 10, 20, 30, 50, 100, 200 ton/day…etc.(depends on the feature of the waste)

Complete Sets of Sewage Treating Equipment of Waste Plastic Washing Line (Customized Products)

- Filtrate reusing system for waste plastic wash water recycling system.

- Remove the suspended solid of the waste water and achieve the purpose of the recycling use.

- Can continuous treatment processing water without interruption, saving water and reducing the water consumption cost.

- The suspended solid of the slurry can feed into the designed filter press to get the sludge cake directly(easy disposal).

- Can solve the water use and waste water treatment of plastic recycling industry, reduce production cost and increase productivity.

- Obtained the CE certification.

- Treating capacity will be 15, 30, 50, 100, 150, 200, 300 M³/hr etc. (depends on the consistency of waste water)

All kinds of Filter Plates / Filter Cloth / Filter Belts’ Manufacturing

- Filter belt is Polyester-material with nice permeability and resistance to chemicals, long life span when using normally.

- Chamber plates & membrane type two time filter press plates are integrally molded by P.P. engineering plastics, light weight, chemical resistance, high filtration speed, good sealing, durable without deformation, long service life.

- Filter cloth mainly used P.P. material, a variety of materials and densities to match a variety of sludge properties.