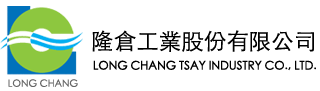

TL / TLM Membrane plate fully automatic type (Filter clothes moving ) series

(Full automatic start‐up, dewatering, unloading, filter cloth cleaning, free manual operation)

Machine outline diagram

Standard specifications (Contact for customized)

| Model | Filter cake press type |

Filter plate type | Filter plate size & quantity (mm/piece) | Filter area (M2) |

treating capacity (Sludge cake volume) (Liter/Lot) | Ref. Machine dimension (Naked type) (Not included base frame height) LxWxH(mm) |

|---|---|---|---|---|---|---|

| TL-63-20 | One time feed press |

Mine type Chamber typ | 630 x 20 | 11.8 | 167 | 5950x1500x2250 |

| -30 | x 30 | 18.0 | 255 | 8710x1500x2250 | ||

| -40 | x 40 | 24.2 | 343 | 9670x1500x2250 | ||

| TL-100-20 | 1000 x 20 | 30.8 | 518 | 6930x1880x2640 | ||

| -30 | x 30 | 47.0 | 791 | 9030x1880x2640 | ||

| -40 | x 40 | 63.2 | 1064 | 11100x1880x2640 | ||

| TL-150-20 | 1500 x 20 | 81.7 | 1360 | 7450x2550x3300 | ||

| -30 | x 30 | 124.7 | 2076 | 9790x2550x3300 | ||

| -40 | x 40 | 166.7 | 2792 | 12130x2550x3300 | ||

| TLM-63-21 | Second time membrane pressurization | Mine type Chamber type + Membrane plate | 630 x 21 | 12.6 | 183 | 6180x1500x2250 |

| -31 | x 31 | 18.9 | 274 | 8040x1500x2250 | ||

| -41 | x 41 | 25.2 | 386 | 9900x1500x2250 | ||

| TLM-100-21 | 1000 x 21 | 34.5 | 558 | 7140x1880x2640 | ||

| -31 | x 31 | 51.7 | 837 | 9240x1880x2640 | ||

| -41 | x 41 | 68.9 | 1116 | 11350x1880x2640 | ||

| TLM-150-21 | 1500 x 21 | 87.6 | 1448 | 7670x2550x3300 | ||

| -31 | x 31 | 131.4 | 2172 | 10010x2550x3300 | ||

| -41 | x 41 | 175.2 | 2896 | 12320x2550x3300 |

Remarks:

|

Features & Usages

|

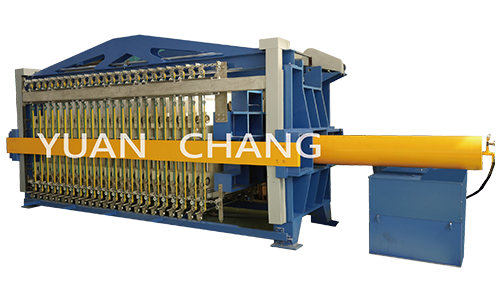

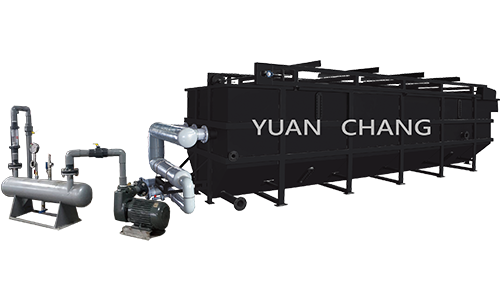

*It can be fully automated from start-up, dehydration, unloading, filter cloth cleaning, free of manual operation. *The filter cloth moves around, the sludge cake can be completely unloaded, and it can be completely free of manual operation, a revolutionary new initiative. *The best weapon for "Ai Industry Artificial Intelligence" that can be fully automated is used in various wastewater treatments. *Feeding from upper part of chamber plate, after filter press, re-press, filter core blowback (optional equipment), unloading, filter cloth cleaning is automatically completed. *The filter cloth driving device drives the filter cloth to move up and down, the filter cake is easy to be automatically removed, and the front cleaning device makes the filter cloth clean inside and outside thoroughly. *The filtering area is large, the dehydration and extrusion increase the dryness of the sludge, the new design concept is easy to operate, and it is an efficient and energy-saving automatic filter press. *Standard PLC control of man-machine, feeding, pressure filtering, unloading of sludge cake, and cleaning of filter cloth can be completed automatically without human operation. *Automatic feeding system for filter cloth walking: sludge cake is completely unloaded without sticking to the filter cloth. Due to the walking design of the filter cloth, even if it is not easy to fall automatically sludge cake is also very easy to peel off automatically when the filter cloth is turned. *Applicable to industrial wastes: industrial sludge, sewage plant sludge, water resources sludge, incinerator fly ash dehydration equipment. |

Application industries and usages

|

*It can be fully automated from start-up, dewatering, unloading, and cleaning. *Filter cloth walking design, the mud cake can be completely removed, and it can be completely free of manual operation, a revolutionary new initiative. *Using the best weapon of “Ai Industrial Artificial Intelligence” in various industrial processes. *Chemical and pharmaceutical industry: solid-liquid separation of chemical raw materials and process filtration and dehydration equipment. *Food processing industry: soy sauce vinegar, fruit juice, soy milk, wine making and other filtration processes. *Solid / liquid separation and dehydration in the process of making (medical) medicine, dyeing (pigment) materials, pottery (porcelain) soil, recycling, grinding, stone, metallurgy and other related industrial processes *Mining sand and gravel industry: solid-liquid separation and dewatering equipment such as cement plants, sand quarries, coal mines, and metal mines. |