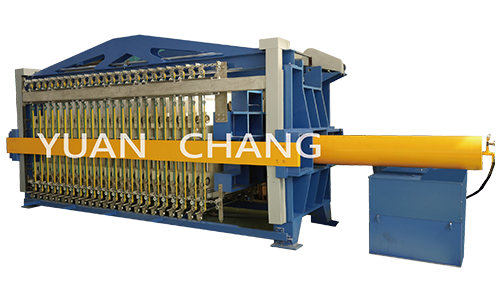

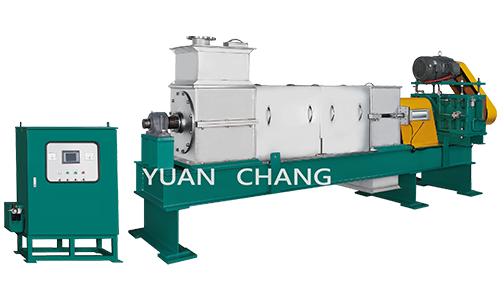

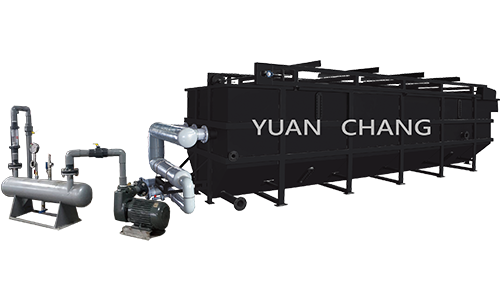

RDT series (Drum type)

Machine outline diagram

Standard specifications (Contact for customized)

Spec. |

Model | ||||||

|---|---|---|---|---|---|---|---|

| RDT-10 | RDT-15 | RDT-25 | RDT-40 | RDT-60 | RDT-90 | ||

| Capacity (m3/hr) Influent concentration (S.S 0.6~2.0%) |

4.0~10 | 7.5~15 | 12~25 | 20~40 | 30~60 | 45~90 | |

| Absolute dryness (kg/hr) | 48~100 | 90~150 | 150~240 | 240~400 | 360~600 | 540~900 | |

| Sludge outflow concentration (%) | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | |

| Power | Drum drive (no step change) |

1/4 | 1/2 | 3/4 | 1 | 2 | 3 |

| Conditioning mixer | 1/4 | 1/4 | 1/4 | 1/2 | 3/4 | 3/4 | |

| Machine material | Standard | Stainless steel (SUS304) | |||||

| Optional | Stainless steel (SUS316/316L) | ||||||

| Referance dimension (mm) |

L | 3050 | 3600 | 4500 | 5000 | 5650 | 6850 |

| W | 1150 | 1150 | 1260 | 1400 | 1600 | 1950 | |

| H | 2000 | 2000 | 2150 | 2500 | 2750 | 3100 | |

| Referance weight (kgs) | 300 | 450 | 700 | 1050 | 1450 | 2180 | |

|

Remarks:

* All models are not equipped with the total drain pan under the filtrate. * The full range of models with static mixing tube is standard. * The amount of treatment, the amount of dryness, and the concentration of sludge outflow depend on type. concentration and characteristics of the sludge. * The specification are accepted outside the specification, and the company reserves the right to design change. * Please ask for the actual installation dimension drawing before ordering. * The washing pump(optional)needs to provide the best water pressure between 4.5 and 6.5kg/cm2 |

Application industries and usages

| * For various low‐concentration sludge (between S.S. 0.4 ~ 1.0%) concentration reduction, it can effectively increase the S.S. concentration to between 3.5 ~ 12%, and indeed achieve the cost‐effectiveness of sludge volume reduction. * Especially suitable for various industrial areas, such as integrated sewage plants, municipal sewage plants, water purification plants, etc., where a large amount of sludge needs to be treated. * Various industrial sludge reduction pre‐concentration treatment. * Tap water is filtered before entering the water and filtered by rainwater. * Engineering drainage and combined wastewater treatment of urban domestic sewage, pulp industry, fiber industry, chemical industry, etc. * Water supply plant, sewage treatment plant, public municipal project, steel/metallurgy, petroleum/chemical, electric power, papermaking, textile/dyeing, brewing, fine chemical, pharmaceutical, coal mine, food and beverage, electronic/circuit, electroplating/surface engineering, building , energy, desalination, hospitals, civil clean water, ships, boilers, and others. * Used in water treatment systems such as blast furnaces, continuous casting, hot rolling and water plants in the metallurgical industry. * Concentration or purification of all solid‐containing slurry in coal, chemical, building materials and water supply industries. |

Features

|

* The structure is simple, the maintenance is easy, the running cost is low and the maintenance cost is small. * The solid capture rate was 95%. * High performance, durable, base. No maintenance required. * Low energy consumption, low polymer consumption . |