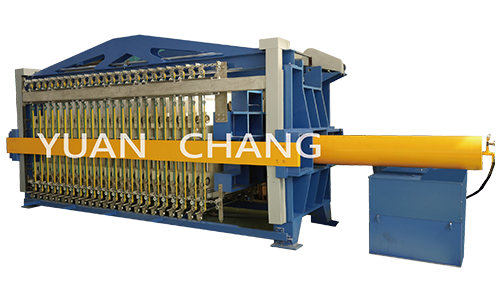

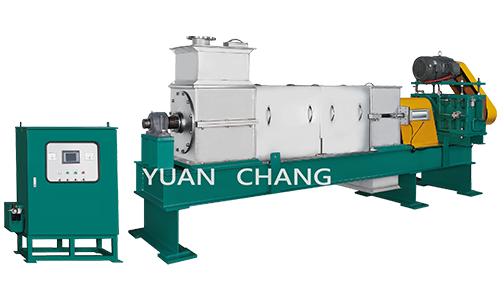

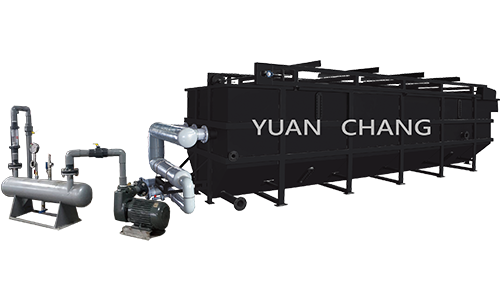

CH Series (hot air drying type - continuous processing)

Machine outline diagram

Standard specifications (Contact for customized)

Spec. |

Model | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CH-100 | CH-200 | CH-300 | CH-400 | CH-500 | CH-750 | CH-1000 | CH-1500 | CH-2000 | CH-3000 | CH-4000 | |||

| Capacity kg/hr (85/75%→40%) |

100 | 200 | 300 | 400 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | ||

| Daily capacity Ton/24hr (85%/75%→40%) |

2.4 | 4.8 | 7.2 | 9.6 | 12 | 18 | 24 | 36 | 48 | 72 | 96 | ||

| Sludge classification | Organic / Inorganic | ||||||||||||

| Heat source | Steam / waste heat / electric heat | ||||||||||||

| Highest treatable moisture content (%) | 85 / 75 (depending on sludge type and moisture content) | ||||||||||||

| Drying temperature (℃) | 100 - 150 (depending on sludge type and moisture content) | ||||||||||||

| Reference dimendion (mm) |

Mainframe | L | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| W | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | ||

| H | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | ||

| Dry tank | L | 1500 | 3500 | 5000 | 6200 | 7500 | 9000 | 12000 | 18000 | 24000 | 36000 | 48000 | |

| W | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | ||

| H | 4400 | 4400 | 4400 | 4400 | 4400 | 4400 | 4400 | 4400 | 4400 | 4400 | 4400 | ||

| Numer of mainframe | 1 | 1 | 1 | 2 | 2 | 3 | 4 | 6 | 8 | 12 | 16 | ||

| Required space (m×m) | 8x3 | 8x4 | 8x5 | 10x6 | 10x8 | 12x8 | 14x10 | 21x10 | 26x10 | 38x10 | 50x10 | ||

Remarks:

|

USAGES

|

* Drying of agricultural and animal husbandry residues and waste. * Drying of tofu residue and food processing residue. * The biological sludge in the primary sedimentation tank and secondary sedimentation tank of the municipal sewage treatment plant in Chenshi is dried. * Inorganic sludge and biological sludge drying in factory wastewater treatment plant. * Drying of organic and inorganic waste in industrial plants. |